Skicka förfrågan

Kontaktinformation

-

Adress

Paibang Industrial Zone, Henggang Town, Longgang District, Shenzhen

-

Tel

-

E-post

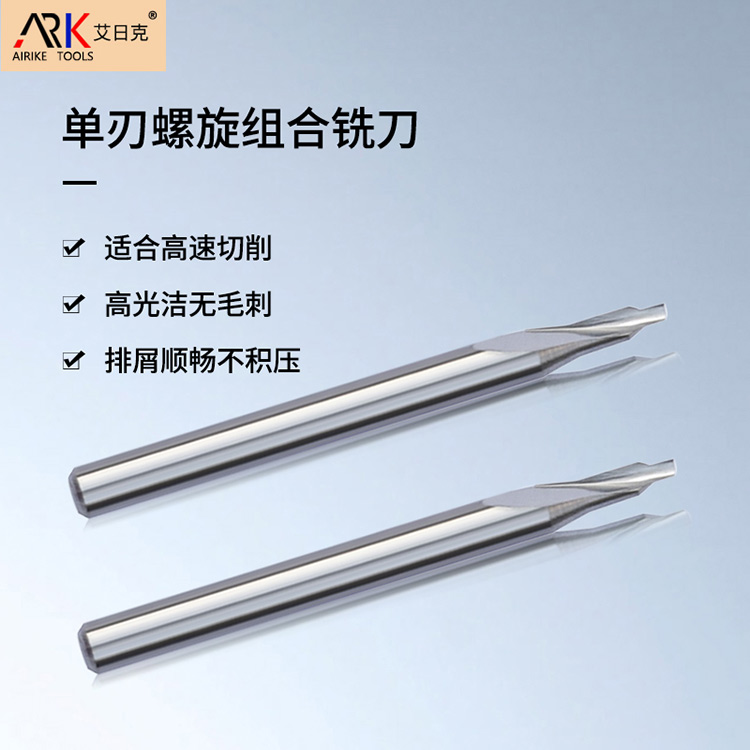

För förfrågningar Zhongyeda graveringsmaskinfräsande skärare, träbearbetningsfräsande skärare, metallklippande frässkärare, vänligen lämna din e -postadress hos oss så kommer vi i kontakt med dig inom 24 timmar.